Lead ingot production is the final stage in the lead-acid battery recycling process, where refined lead is cast into ingots for further use or sale.

In this article we will provide a detailed and informative explanation of the process of lead ingot production in a battery recycling facility. The recycling process can be broadly divided into five stages: pre-treatment, breaking and separation, smelting, refining, and ingot production.

Lead ingots manufacturing process

1. Pre-treatment:

The first step involves collecting and sorting used lead-acid batteries, which are typically sourced from automotive, industrial, and stationary applications. The batteries are sorted based on their type, size, and condition. Damaged batteries with potential acid leakage are neutralized using sodium bicarbonate or other suitable chemicals before proceeding to the next stage.

2. Breaking and separation:

Batteries are fed into a mechanical crusher or hammer mill, which breaks them into smaller pieces. This process helps in the separation of the different components, such as lead grids, lead oxide paste, separators, and electrolyte (sulfuric acid solution). A series of vibrating screens, hydro-separators, and sink-float tanks are used to separate these components based on their specific gravities. The lead grids and lead oxide paste, which are heavier, settle at the bottom, while lighter materials such as separators and plastic casing float to the top. The electrolyte is drained and treated separately for neutralization and water recovery, a process that is even more enhanced in our latest Battery Breaker launch called Gravity Breaker that levarages massively on the usage of natural forces such as Gravity and/or Inertial Mass.

3. Smelting:

The lead-bearing materials, including the lead grids and lead oxide paste, are transferred to a smelting furnace. The furnace can be a rotary kiln, short rotary furnace, or blast furnace, depending on the plant’s capacity. Our process lies on fixed rotary furnace technology engineered by our R&D and improved over the years on the field to reduce at minimum the NG consumption/cycle while improving the time to smelt.

4. Refining:

The lead bullion obtained from the smelting process usually contains impurities such as copper, tin, antimony, arsenic, and other trace elements. To obtain pure lead, the bullion undergoes refining using one or a combination of the following methods:

- Pyrometallurgical refining: This method involves the controlled oxidation of impurities in a refining kettle or furnace. By adjusting the temperature and introducing air, the impurities are oxidized and form a slag, which is skimmed off the surface of the molten lead. Based on this technology, in GME we’ve been developing a vertical kettle leveraging on Gravity force to reduce at ZERO the oxidation production during pouring step.

- Electrolytic refining: In this method, the impure lead serves as the anode, and a pure lead sheet serves as the cathode in an electrolytic cell containing a lead fluosilicate solution. As an electric current is applied, pure lead deposits onto the cathode, while impurities either remain in the anode sludge or dissolve in the electrolyte.

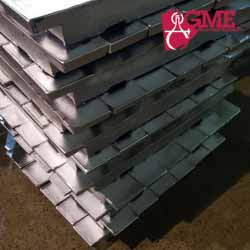

5. Ingot Production:

The fifth step of the lead ingot process involves casting the refined lead into ingots. This stage is crucial for preparing lead in a form suitable for storage, transportation, and further processing or sale.

The process entails the following activities:

5.1 Cooling the molten lead: After the refining process, the pure molten lead is maintained at a specific temperature, typically between 327°C to 350°C. This temperature range ensures that the lead remains in a liquid state and is suitable for casting.

5.2 Casting the ingots: The molten lead is poured or transferred from the refining furnace or kettle to ingot molds or a continuous casting machine. Ingot molds are typically made of cast iron or steel and are designed to hold a specific weight of lead, such as 25 kg, 50 kg, or 1 metric ton.

In the case of continuous casting, the molten lead is fed into a water-cooled mold, which solidifies the lead into a continuous strand or bar. The strand is then cut into the desired length, forming individual ingots.

5.3 Cooling and solidification: The molten lead in the molds or continuous casting machine cools and solidifies, forming ingots. The cooling process takes place naturally or is expedited using air or water cooling systems. The cooling duration depends on the ingot size and the employed cooling method.

5.4 Ingot removal and finishing: Once the lead ingots have solidified, they are removed from the molds or continuous casting machine. The ingots may be cleaned or deburred, if necessary, to remove any surface irregularities or residues. The finished ingots are then stacked, packaged, and prepared for storage.

Comments are closed.