Tag: battery recycling

How a lead car batteries recycling plant works

GME’s recycling technical engineers would to introduce you to the process of lead acid battery recycling and its significance in the automotive industry. With the growing demand for sustainable solutions, recycling lead acid batteries is becoming increasingly important to reduce environmental impact and conserve resources. Lead acid batteries are commonly used in vehicles, and their disposal has become a crucial

Unlocking the Process: How Lead Ingots are Produced

Lead ingot production is the final stage in the lead-acid battery recycling process, where refined lead is cast into ingots for further use or sale. In this article we will provide a detailed and informative explanation of the process of lead ingot production in a battery recycling facility. The recycling process can be broadly divided into five stages: pre-treatment, breaking

What is the difference between lead acid and lithium batteries

As technical engineers specializing in the design of lead-acid battery recycling plants, GME’s team would like to provide a detailed and informative comparison between lead-acid and lithium-ion batteries. Both types of batteries serve as power storage devices with distinct advantages and disadvantages, depending on the application. Chemistry and Components Lead-acid batteries The lead-acid battery comprises a set of electrochemical cells,

The Ultimate Guide to Lead Smelting: What It Is and How It Works

Lead smelting is a crucial step in the lead battery recycling process, which involves the extraction of lead from used batteries and the recycling of this lead for use in new batteries or other industrial applications. In a lead battery recycling plant, the lead-acid batteries are first broken down into their component parts, which typically includes the lead plates, lead

Learn How to Recycle Lead Acid Batteries Effectively

Can lead acid batteries be recycled? Lead-acid batteries are widely used in various applications, such as automotive, industrial, and renewable energy systems. However, they have a limited lifespan and eventually need to be replaced. This creates a significant environmental challenge, as lead-acid batteries contain hazardous materials, such as lead and sulfuric acid, which can be harmful to human health and

Recycling plant manufactoring: how to reduce and optimize production costs

There are several actions that can be undertaken to reduce the production costs of a battery recycling plant: Optimize process efficiency: Improving process efficiency can help reduce production costs by minimizing waste, energy consumption, and labor costs. This can be achieved by selecting the most efficient recycling technology, optimizing production processes, and utilizing automation and software control systems. Utilize renewable

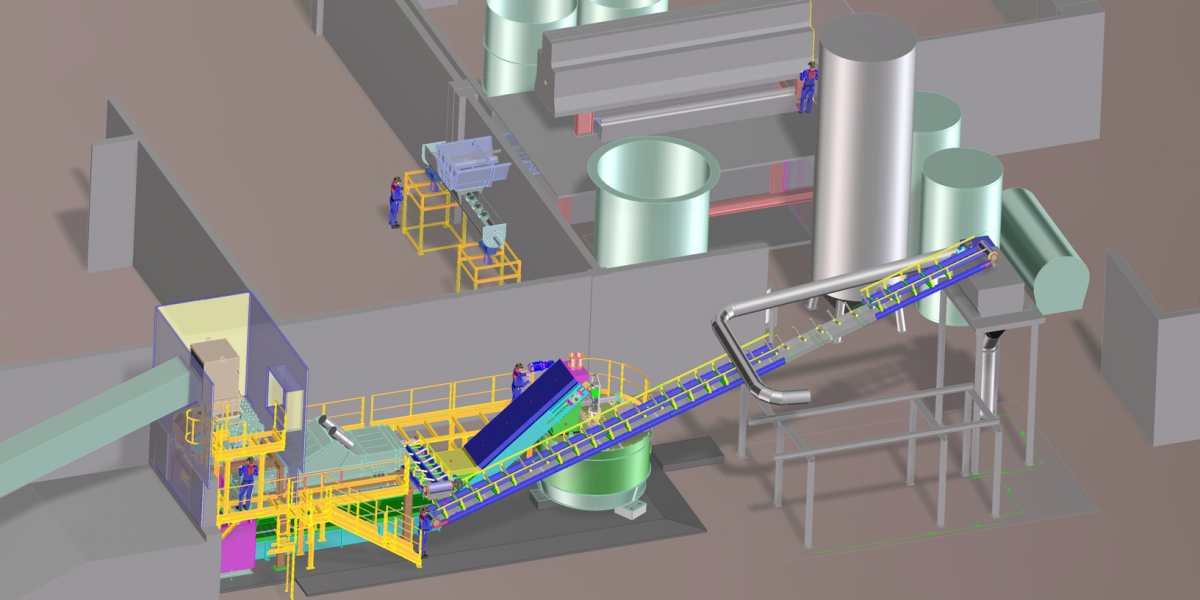

What is a Battery breaker plant

A battery breaker plant is a facility that is used to recycle batteries by breaking them down into their component parts. The process typically involves crushing the batteries to separate the different materials, such as lead, acid, and plastic, which can then be processed further and reused in the production of new batteries or other products. Battery breaker plants are