Suhail Project Description

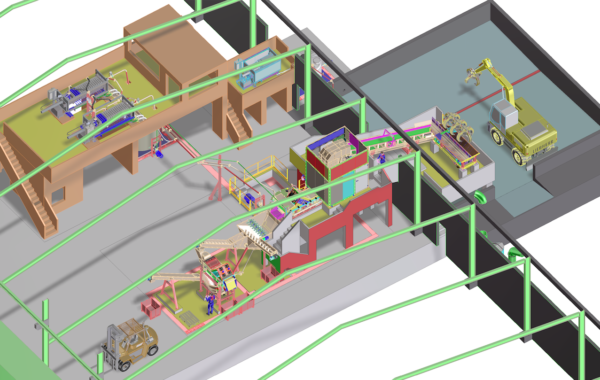

In 2023, GME was selected for a new Lead Battery Recycling Plant Project from SUHAIL INDUSTRIAL HOLDING GROUP, one of the leading holding group of companies that produce, and export processed non-ferrous metals, stainless steel, and plastic from the Qatar. Its strength and foresight has led the Company to be set as the first Smelting and Refining facility to produce Pure Lead ingots in the whole State of Qatar. The project consisted in a complete Battery Breaker plant manufacturing with a capacity of 10 tons/hour as step 1 with a complete Smelting, Refining and Casting line as a step 2. GME was responsible for the engineering, procurement, manufacturing and the installation supervision of the entire plant.

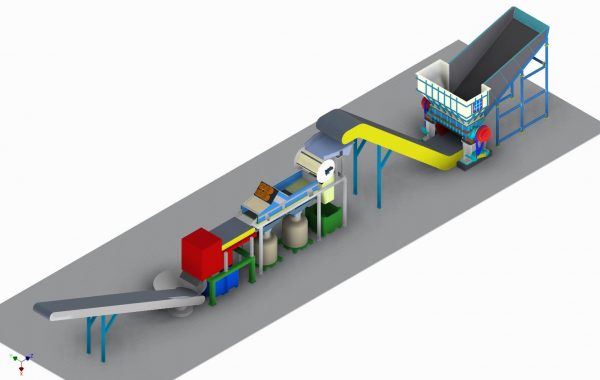

Performed activities: 2023, battery recycling plant cap. 50.000 tpy supplying, with

Battery breaker unit, 10 tph capacity, including

Water Neutralization unit, including:

Projects specs

Sector: batteries recycling plant

Commissioned: SUHAIL INDUSTRIAL HOLDING GROUP

Country: Doha Industrial area, Doha, State of Qatar

Performed activities: Battery recycling plant cap. 50.000 tpy supplying, with battery breaker, water neutralization unit, wet scrubber, Automatic Charging Station, N.1 rotary furnaces 4 M3, Set of kettles 35 Tons, N.1 ingots casting machine.

Capacity of the plant: 50.000 tpy

Rotary furnaces 4 m3 capacity

Set of kettles 35 Ton

N.1 ingots casting belt, 9 ton per hour capacity with 25 kg ingots

N.1 variable speed casting belt

Discover the Suhail Project

Discover our related recycling plants

Comments are closed.