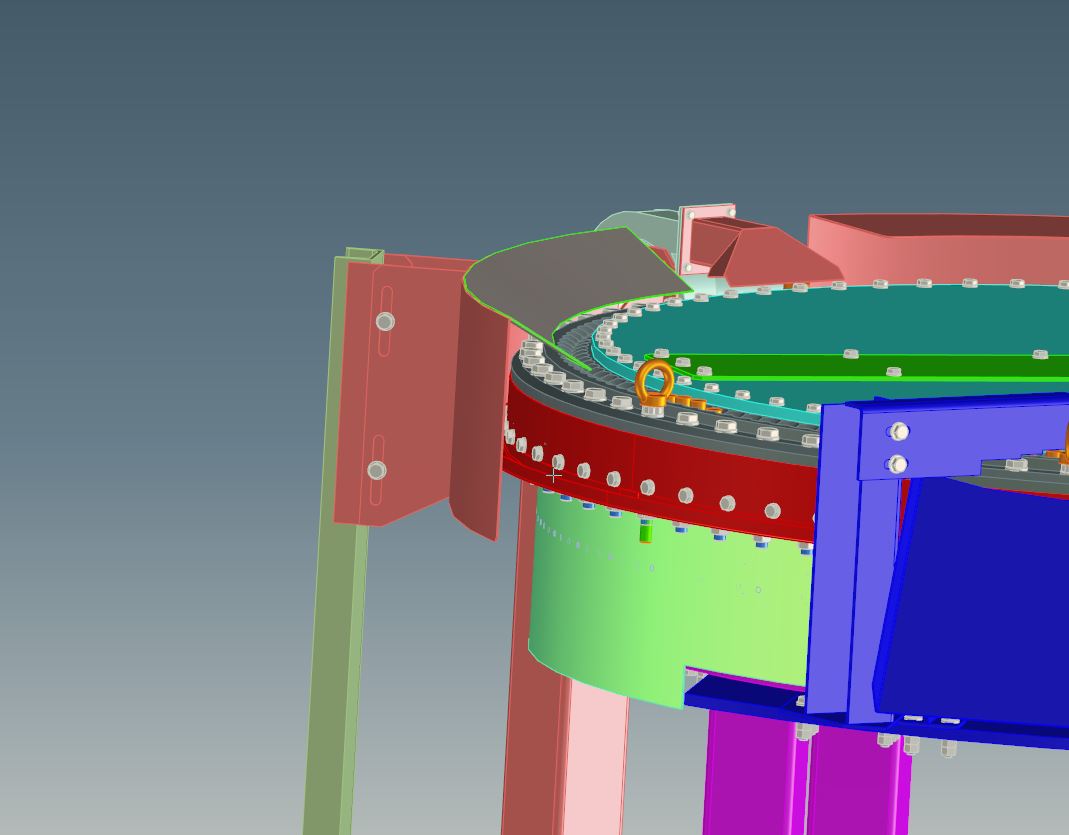

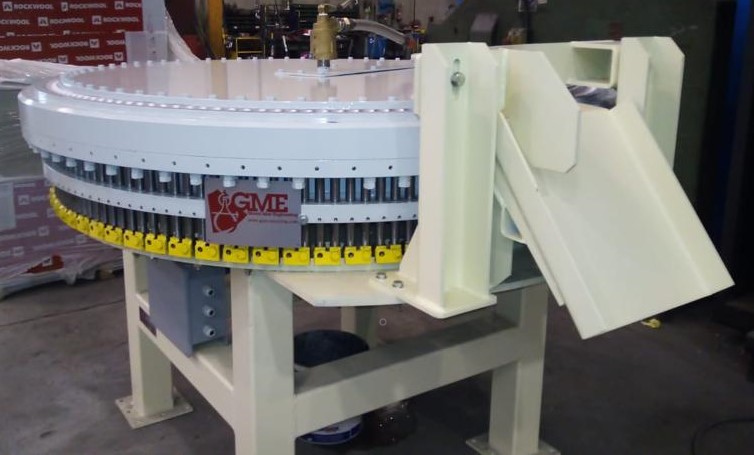

LCC MACHINE Description

The scope is cast the refined soft lead into kettle to lead cylinder casting machine producing cylinders dimensions:

Required items:

The customer can cast the soft lead directly in the cylinder casting machine to produce the cylinders for the mills, avoiding the re-melting operation of the ingots, by saving fuel and ingots handling.

The unit is studied to connect directly to the soft lead kettle.

Technical data

Diameter of cylinder: 22 mm

Height of the cylinder: 35 mm (The dimensions of the cyclinders can be modified according the requirement of the client.)

Number of revolutions: 7 rpm/min

Specific weight Pb : 1 Kg/dm3

Weight of each cylinder: 166,20 gr.

Theoretical productivity : 5 ton/h, 500 cylinders/min

Machine dim: 1400 mm height: 1700 mm large

Number of cylinders produced each lap: 150

Number of cavity required: 150

Diameter of the wheel: 1650 approx. mm

Electricity: 3ph/400V/50 Hz

Installed electric motor power for crown rotation: 3,0 kW

Required soft water from recirculating & cooling system: 2 m3/h at temp.18-25 °C

Compressed air: 1200 l/h at 7 bars

Machine description

LEAD CYLINDER CASTNG MACHINE PURPOSE

The scope is cast the refined soft lead into kettle to lead cylinder for lead oxide production by casting machine. The customer can cast the soft lead directly in the cylinder casting machine to produce the cylinders for the lead oxyde, by-passing the ingots re-melting, saving fuel and ingots handling. The unit is also studied to connect directly to the soft lead kettle.

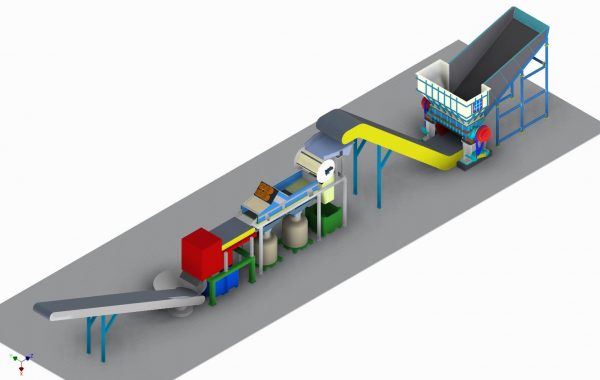

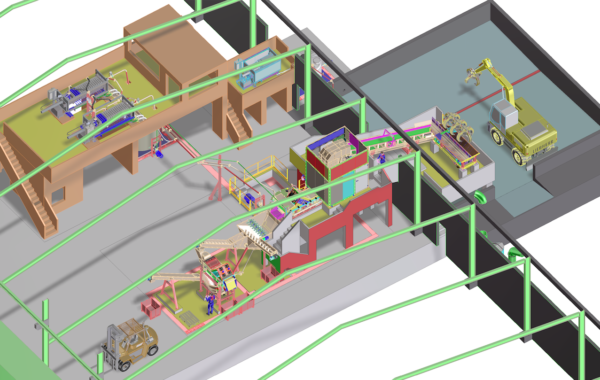

Discover our related recycling plants

Comments are closed.