Decoating, also referred to as delacquering, is a process that removes the various coatings applied to aluminium products, which can range from beverage cans and food containers to construction materials and car parts. The coatings, which can include paint, ink, plastics, oils and lacquers, are designed to suit the product’s specific use but can present challenges when reprocessing aluminium. They can reduce recovery rates and pose safety risks in processing environments.

However, decoating offers several benefits to aluminium recycling operations. Firstly, it reduces metal losses, which is crucial for maximising aluminium recovery. Without decoating, the direct melting of coated scrap aluminium could result in substantial metal loss. Secondly, it enhances plant safety by eliminating the risk of explosions caused by trapped water in dirty scrap. Lastly, decoating allows for a broader range of scrap types to be processed, offering companies flexibility in a volatile market.

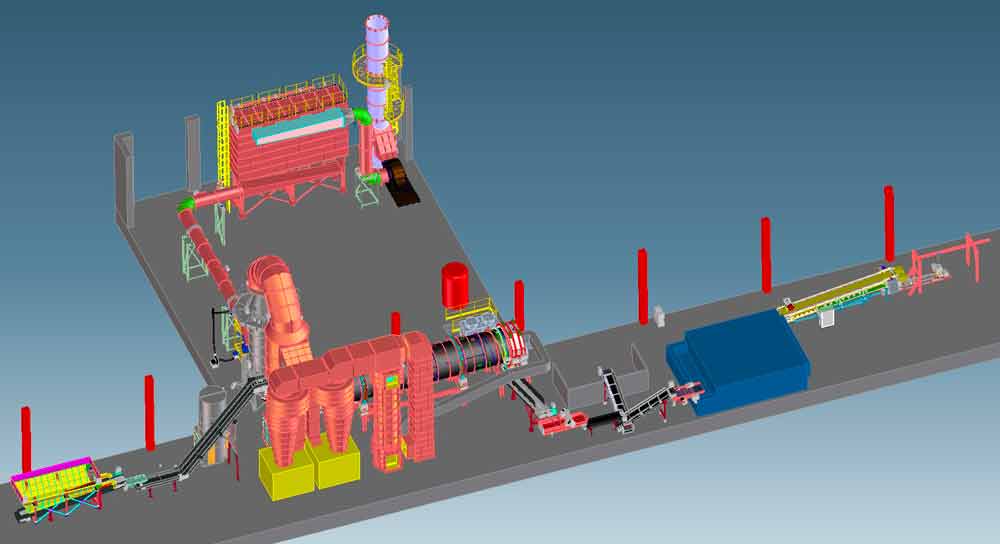

Decoating systems applications

The application of these decoating systems finds use in all cases where it is necessary to restore the surface of the coated workpiece to its initial nature. This technology can be used on both carbide and steel tools; the workpieces to be treated are immersed in a tank containing a particular mixture. The time for perfect export of the coating will depend on the type of metal, steel or carbide, and the type of coating in the workpiece. At the end of the process the part will, therefore, be ready to be trimmed or otherwise, coated and used as new.

The solutions used guarantee perfect compliance, of the “Decoating System” with current anti-pollution regulations.

At GME, in order to be increasingly green, with our team of engineers we have developed systems with zero-impact Hydrogen Burners, but modulable so that they can be used 100% Hydrogen, 50/50 or 100% Natural Gas

Recycling systems without decoating: an outdated technology

Aluminum recycling without decoating is another alternative, but less efficient in terms of metal recovery and emission control.

However, the tilting rotary kiln is a flexible recycling equipment to process almost any type of aluminum scrap and slag, always assuming the availability of flows and the possibility of recycling salt slag.

It can process a wide variety of materials, from casings with inserts, cans, chips, slag, etc.

The benefits and cost savings provided by decoating make it an appealing option for many aluminium recycling operations. For more information on Aluminium UBC Cans Recycling Line, contact us now

Comments are closed.