As recycling plant engineers in the field of recycling, one of the crucial components in aluminum recycling facilities is the Aluminum Dry Sole Furnace. This furnace plays a pivotal role in melting down aluminum scrap to be reused in various applications.

The Aluminium Dry Sole Furnace is a type of furnace very versatile, capable of handling various types of aluminum scrap, including engine blocks, high density bales, mixed conglomerate of aluminium scrap, ingots, painted, and unpainted scraps. The Term “dry sole” refers to the absence of a molten bath of aluminium within the Furnace.

Here’s a description of its components and how it operates:

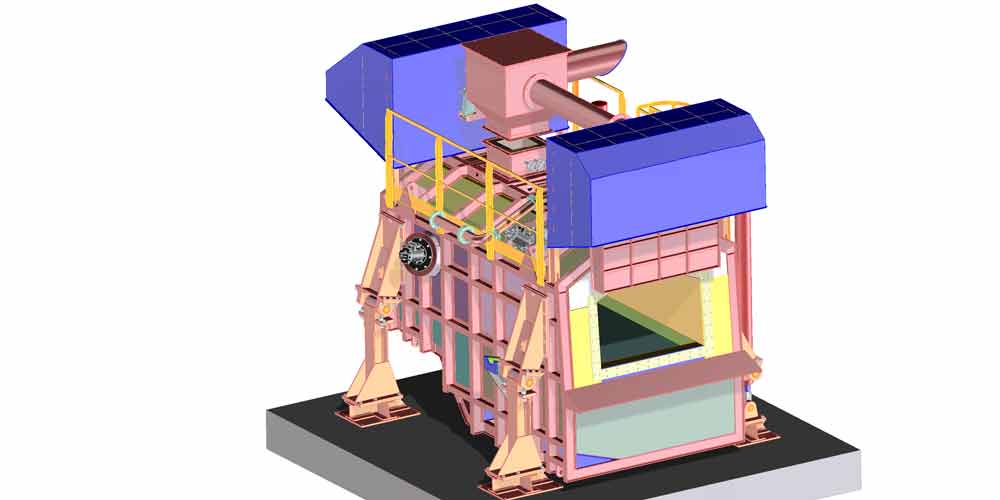

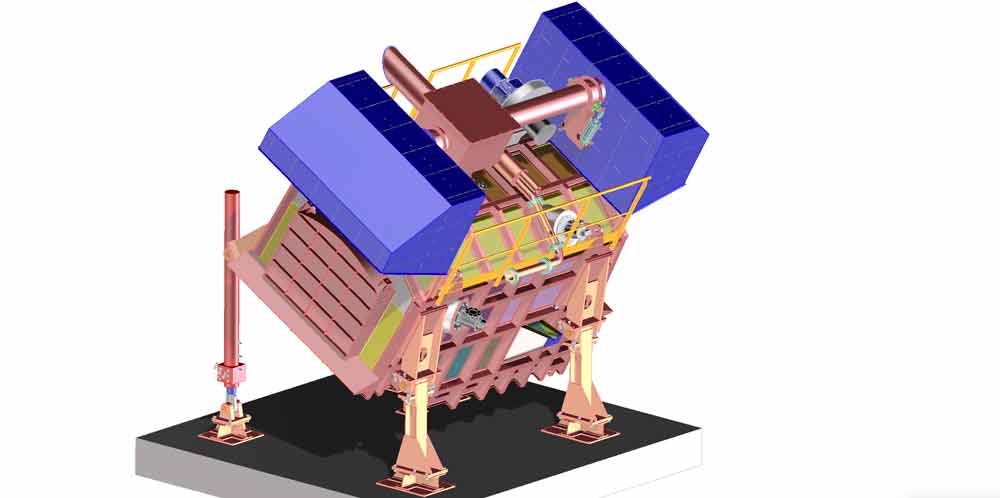

- Structure: The furnace typically consists of a refractory-lined chamber with a roof for insulation. The structure is robust to withstand the high temperatures involved in aluminum melting.

- Burners: The furnace is equipped with multiple burners, often running on natural gas or oil, which provide the heat necessary to melt the aluminum.

- Heat Transfer: Instead of immersing the aluminum directly into a molten bath, the dry sole furnace uses intense heat from the burners to radiatively transfer heat to the aluminum scrap placed on the furnace floor.

- Aluminum Charge: Aluminum scrap, such as recycled aluminum parts or ingots, is loaded onto the furnace floor. The heat from the burners gradually raises the temperature of the scrap, causing it to melt.

- Temperature Control: Temperature control systems monitor and regulate the heat within the furnace to ensure efficient melting without overheating or underheating the aluminum.

- Tapping and Casting: Once the aluminum reaches the desired molten state, it can be tapped from the furnace and cast into molds to form ingots or other desired shapes. This process is typically controlled manually or through automated systems.

- Efficiency: Dry sole furnaces are known for their energy efficiency compared to other types of furnaces, as they eliminate the need for a large volume of molten aluminum, which requires significant energy to maintain.

- Environmental Considerations: While dry sole furnaces are more energy-efficient, they still produce emissions from the combustion of fuels. Efforts are made to optimize combustion processes and implement pollution control measures to minimize environmental impact.

Overall, the aluminum dry sole furnace provides a reliable and efficient method for melting aluminum scrap and producing high-quality aluminum ingots for various industrial applications.

GME’s Dry Sole Furnace Potential

GME RECYCLING, with its 30 years of experience in designing recycling plants, presents a formidable range of machinery, including the Dry Sole Furnace. The technical characteristics of GME’s Dry Sole Furnace exhibit high capacity, precise control, and robust construction, aligning with the demands of modern recycling facilities. With its advanced features and efficiency, GME’s equipment promises to enhance the productivity and sustainability of aluminum recycling operations worldwide.

GME’s Aluminum Dry Sole Furnace: Components and Functionality

The Aluminum Dry Sole Furnace is a specialized equipment designed to melt aluminum scrap efficiently for recycling purposes. It’s a critical part of the aluminum recycling process, allowing for the transformation of scrap aluminum into molten metal ready for casting or further processing.

- Furnace Capacity: the furnace can handle up to 2500 Kg of molten aluminum.

- Melting Capacity: it can melt approximately 800 Kg of aluminum per hour.

- Temperature Control: the furnace can reach a maximum bath temperature of 750°C, while the refractory can withstand temperatures up to 1200°C.

- Combustible Gas: operates on natural gas, providing efficient and cost-effective energy for the melting process.

- Burners: the furnace is equipped with three burners. Two burners produce tapered flames with a maximum rating of 700,000 KCal/h each, while one burner generates a flat flame with a maximum rating of 220,000 KCal/h.

- Power Management: it features adjustable power management from 20% to 100%, enabling precise control over the melting process.

- Auxiliary Services: the furnace operates on a three-phase, 380 V/50 Hz power supply and requires 24 V auxiliary services.

- Gas Pressure Feeding: gas pressure feeding ranges from 0.3 to 1 bar, ensuring optimal combustion and efficiency.

- Weight: the furnace weighs approximately 40,000 Kg, indicating its robust construction and stability.

- Melting Loss: depending on the type of scrap charged, the melting loss varies from 1.5% to 15%, with different scrap materials affecting the efficiency of the melting process.

- Product Fiches - Tecnical Characteristics - DRY SOLE FURNACE

-

Furnace capacity 2500 Kg molten aluminium Melting capacity ~800 Kg / h. Bath max temperature 750 °C Refractory max temperature 1200 °C Combustible gas Natural gas Number of burners 3 Burners’ melting chamber tapered flame (n.2) max rating 700.000 KCal/h Burners’ holding chamber flat flame (n.1) max rating 220.000 KCal/h Max rating 300.000 KCal/h Max consumption 35 m3/hour (Natural Gas) Installed power management From 20% to 100% with limit of maximum Power supply Three-phase, 380 V/50 Hz Auxiliary services 24 V C.C./A.C. (Left out starting trasformers and UV probes, working at 220 V A.C.) Gas pressure feeding from 0.3 to 1 bar Max consumption 110 Nm3/h Weight 40.000 Kg

Melting loss: depending on kind of scrap charged; 1. Al ingots charged: 1,5%, 2. clean Al casting blocks charged: 2.5%, 3. dirty Al casting blocks charged: 5%, 4. light Al not painted scrap charged: 9%, 5. light Al painted scrap charged: 12% to 15%, average values

Benefits for recycling facilities brought in by Aluminum Dry Sole Furnace

The Aluminum Dry Sole Furnace presents a multitude of advantages for recycling facilities:

- Enhanced Efficiency: With its high melting capacity and precise temperature control, the furnace significantly boosts the overall efficiency of the recycling plant. This allows for faster processing of aluminum scrap, leading to higher throughput and productivity.

- Cost-Effectiveness: By utilizing natural gas as its primary fuel source, the furnace presents a cost-effective solution for melting aluminum scrap in comparison to traditional methods. This helps recycling facilities manage operational costs while maintaining high-quality output.

- Versatility in Processing: The furnace’s capability to handle various types of aluminum scrap, including ingots, painted, and unpainted scraps, adds a layer of versatility to the recycling process. This versatility enables recycling facilities to adapt to different types of scrap materials, ensuring efficient utilization of resources.

- Reduction of Melting Loss: Through meticulous management and selection of scrap materials, the furnace minimizes melting loss during the recycling process. This reduction in melting loss translates to higher yields of recycled aluminum, optimizing resource utilization and minimizing waste.

In essence, the Aluminum Dry Sole Furnace serves as a cornerstone in modern recycling facilities, offering enhanced efficiency, cost-effectiveness, versatility in processing, and reduction of melting loss. Its integration into recycling processes represents a significant step towards sustainable aluminum recycling practices.

Contact us to request a consultation or quote for your new “aluminum dry soling furnace”

Comments are closed.