MAX 1700: the Hammer Mill Aluminum scrap and Metal scrap

Introducing the NEW MAX 1700 Hammer Mill

Are you in the business of recycling metal scraps? If so, you’re likely aware of the challenges and opportunities that come with it. Recycling metal not only contributes to sustainability but also holds significant value in the scrap metal industry. To enhance your recycling efforts and maximize efficiency, let’s introduce you to our latest innovation: the MAX 1700 Hammer Mill Shredder.

The MAX 1700 is a cutting-edge machine engineered to revolutionize metal scraps recycling. Here’s what sets it apart:

Robust-Construction

The MAX 1700 features a machine engineered on a single cast iron rotor with several swinging hammers. Its heavy-duty construction ensures durability, even under the toughest recycling conditions.

Hardened Steel Armors

Inside the machine’s casing, you’ll find hardened steel armors that provide unmatched protection. These armors are designed to withstand the wear and tear of constant metal shredding.

Smart Check Technology

Case equipped with Smart Check Technology, a movable side part motorized by a couple of hydraulic cylinders, for easy inspection of the rotor and the hammers

Powerful Rotor

The rotor is powered by a 500 kW, 4-pole electric motor through a set of pulleys with V-belts. This ensures efficient and consistent shredding performance.

Long-Lasting Hammers

The swinging hammers are equipped with DUOface Technology, featuring special hardened steel. This technology extends the operative life of the hammers, reducing the frequency of replacements.

Vibration Control

To prevent vibrations from affecting your foundation, the MAX 1700 is fully suspended on a set of elastic supports. This feature ensures stability and minimizes the impact on your recycling facility.

Efficient Charging Hopper

The charging hopper is specially designed to avoid the rejection of pieces during the crushing process. This means less material waste and more efficient recycling.

Customizable Discharging Grids

The MAX 1700 comes with multisize discharging grids featuring different openings. You can easily adjust these grids according to the desired dimensions of the crushed material, enhancing flexibility in your recycling process.

Uncrushing Piece Management

To address uncrushed pieces, the machine includes an overflowing window, allowing you to identify and manage them effectively.

Technical Specifications

| Motor Speed | 1450 rpm |

|---|---|

| Rotor Speed | 730 rpm |

| Rotor Dimensions | 1600×900 mm (lenght x diameter) |

| Hammers | 28 hammers weighing 50 kg each |

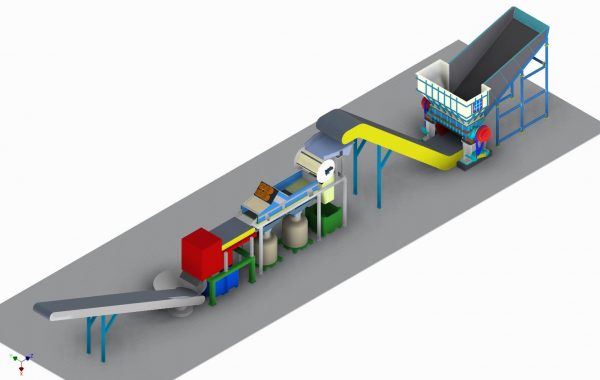

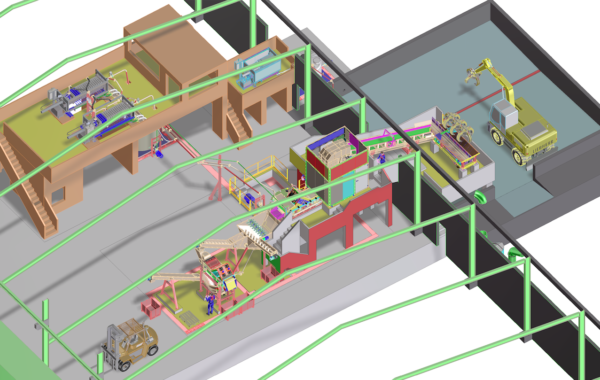

MAX 1700 NEW equipment components

Maximize metal scraps recycling efficiency with max 1700, our new hammer mill

Contact Us to speak about your new MAX 1700

Contact Details HeadQuarter