Recibat Project Description

Performed activities in 2015.

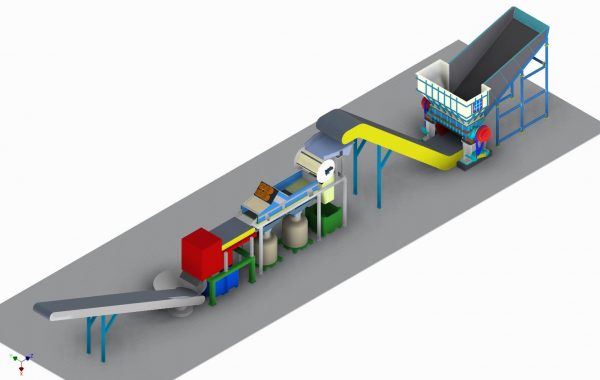

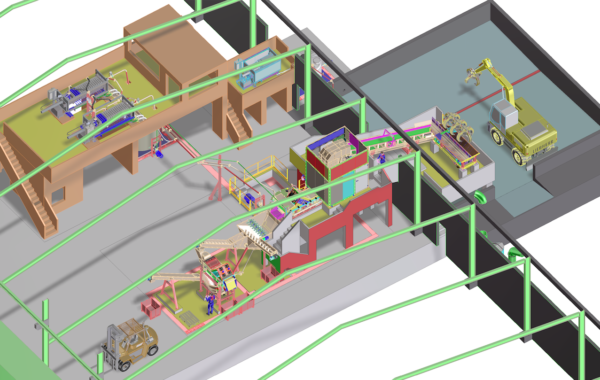

Revamping and modernization of the existing battery breaker, supplied by GME’s engineer, with:

Performed activities in 2016

New dross chain skimmer for existing kettles with the aim of automating and accelerating the removal of slags (ashes) from the surface of the bath in the lead refining kettles.

Performed activities in 2017

New 30 ton kettle with modifications to the existing refinery and ingot mold to pour some particular alloys from the bottom, by gravity, of the kettle, such as calcium alloy.

Supply of new design crucibles, in special cast iron, for casting from an existing rotary oven to replace existing ones that are not suitable.

Projects specs

Sector: batteries recycling plant (full factory)

Commissioned: RECIBAT SARL

Country: BERRIANE – ALGERIA

Performed activities:engineering, procurement, realization and installation supervision

Material: stainless steel AISI 316 and Polypropylene

Capacity of the plant:5 Tons/hour of exhausted batteries

Performed activities in 2019

Supply of a new 2 m3 rotary lead furnace

The furnace has been designed to be loaded with an automatic vibrating channel loader, thus improving the time and effort for loading the furnace itself.

Discover our related recycling plants

Comments are closed.