German Company Project Description

New rotary furnace cap. 4 m3 (10 Ton with paste) with automatic loader and with de-dusting system.

The loader shall be pre-loaded with 4 m3 of pre-mixed charge.

When furnace ready to be loaded the stainless steel metallic belt of loader transfers the 4 m3 charge from hopper, via the vibrating channel, into the rotary furnace.

The furnace rotation is provided with couple of electric gear boxes managed by inverters, the charge heating is by self-cooled single pass oxy-gas burner, the exhaust (process) gas are collected on rear part of the furnace into one chamber providing for crust/dust settling and for temperature & pressure control and the lead metal and slag are poured to crucibles by gravity from center sheel of furnace, guarantee the batch cycle max 3,5 hours, the gas consumption max 30 Nm3/ton of lead bullion casted and slag with max 4% of lead content.

The furnace shell is competely covered by house collecting all the polluting fumes escaping during melting and casting phases. Together the process gas and the hygienic air collected by shell-house are pre-mixed in one mixing chamber and then sent to couple of bag filter working at high temperature, the bags of the bag filters are pre-coated by lime to prevent spark firing of the bags and to capture the toxic gas like SO2 before discharging into atmosphere, all the system is according the EU regulations.

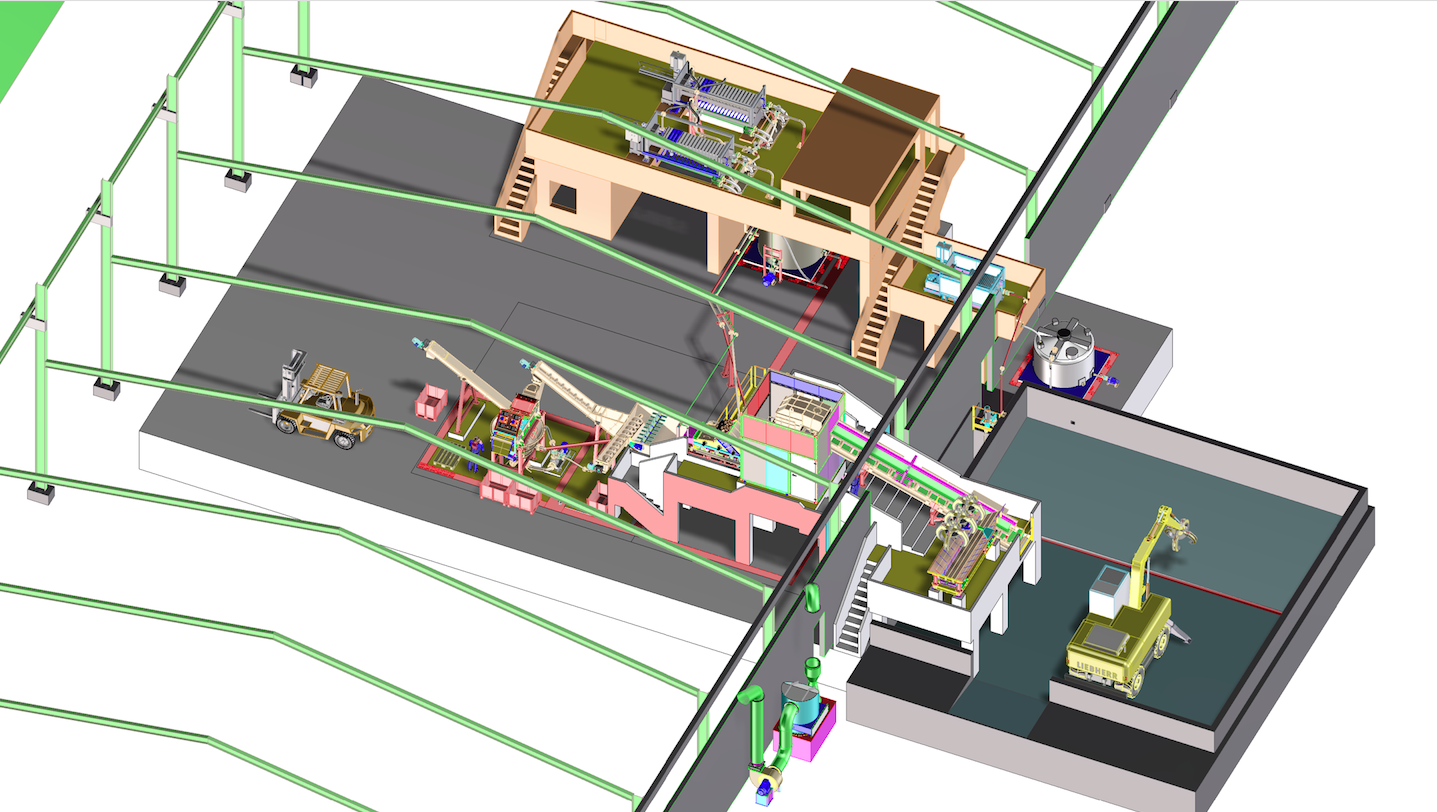

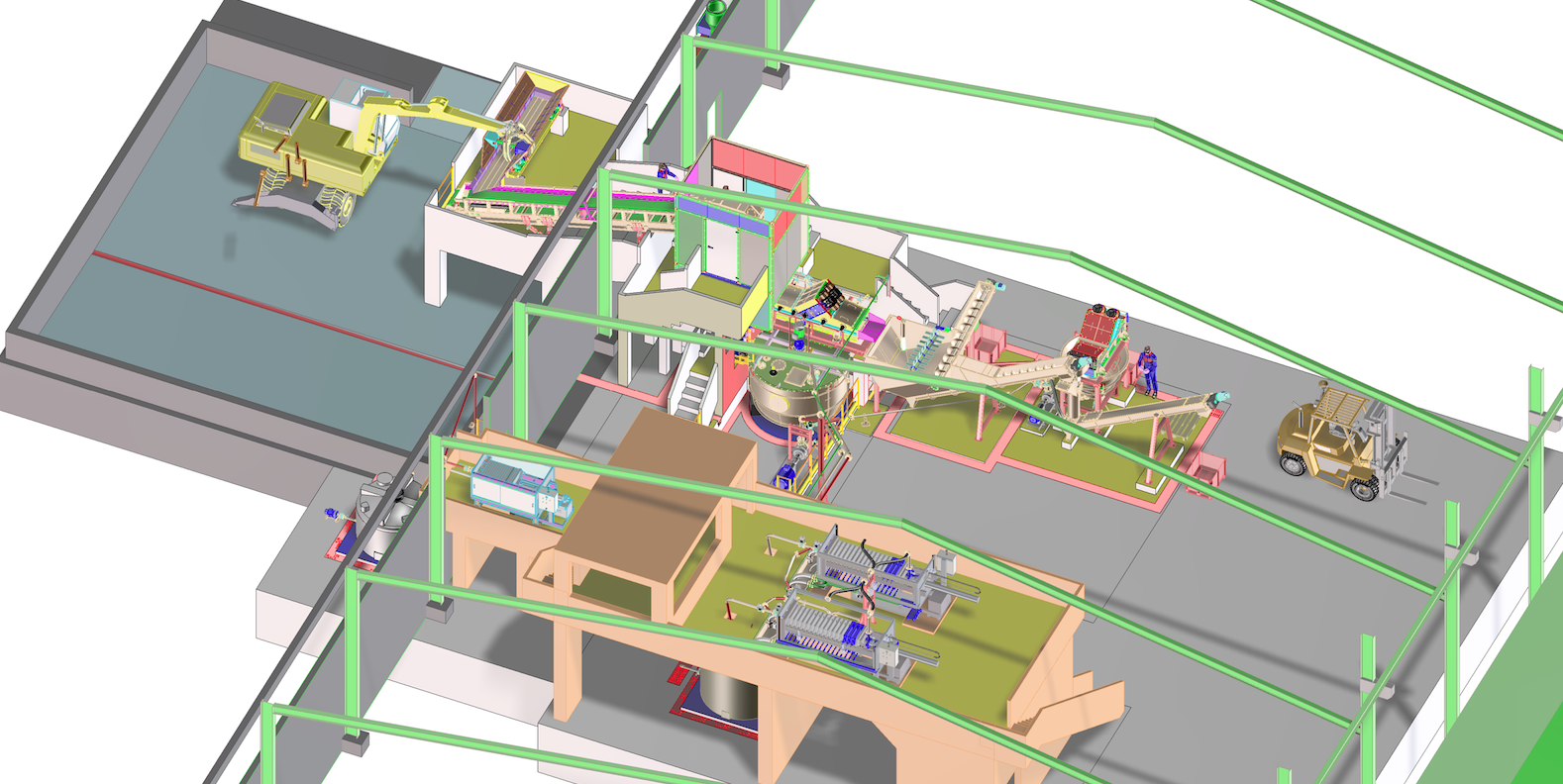

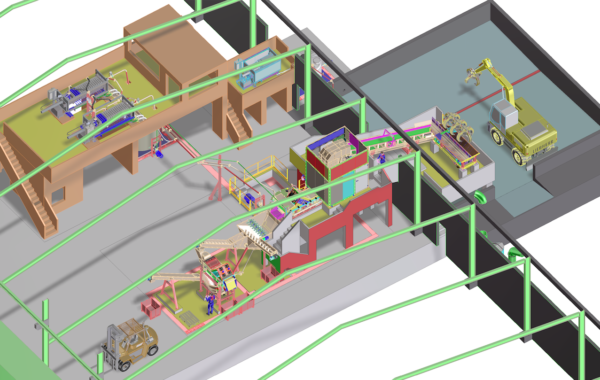

Performing activities 2021: new refinery based on 4 kettles 40 Ton, where 2 are with bottom pouring hole for gravity casting plus one kettle 25 Ton for calcium alloy only.

Projects specs

Sector: batteries recycling plant (braker)

Commissioned: GERMAN COMPANY FOR MANUFACTURING BATTERY

Country: ELSALHIA ELEDEDA- 2nd Industrial Area- Zagazig – EGYPT

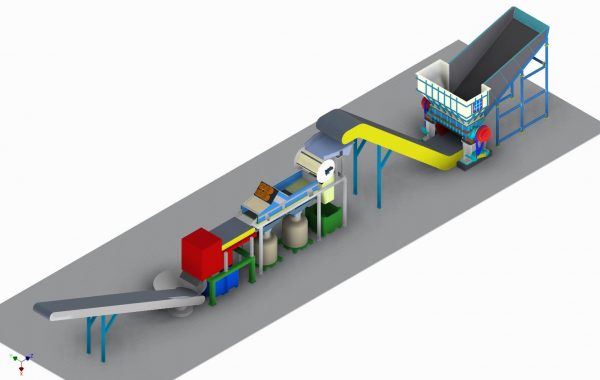

Performed activities: supplying of new battery breaker cap. 5 tph

Material:stainless steel AISI 304/316 and Polypropylene

Capacity of the plant:5 Tons/Hour of batttery scraps

Performing activities 2020-2021

Discover our related recycling plants

Comments are closed.